Sustainability Journey

At Easyshed, we empower sustainability through every step of our journey.

We aim to make a difference.

One shed at a time.

Our adventure thus far

With over 40 years in the business, Easyshed is more than just a brand; we have a commitment to sustainability and innovation. As we continue to grow, we're becoming more aware of the positive impact we can have on our environments, both local and global. This has kick-started our mission to become a truly sustainable brand. Join us on this journey towards a greener, more sustainable future, where every shed embodies our dedication to responsible manufacturing.

Sustainable Packaging

We've transitioned from traditional packaging with heavy ink usage to eco-friendly, recyclable boxes. Our consolidated packaging on stacked pallets ensures efficient shipping directly to consumers, minimising unnecessary packaging materials. We also re-use 95% of our pallets, minimising timber wastage which harms our environment.

Minimising Waste, Maximising Efficiency

Our commitment to waste reduction is reflected in our meticulous production processes. By crafting our sheds on a made-to-order basis, we eliminate the possibility of 'dead stock' which ultimately ends up in landfill. Further to that, all sheds deemed to be of sub-par quality are repurposed or sold as 'seconds', rather than discarded. Any remaining waster is directed to metal and cardboard recyclers, contributing to a circular economy. Additionally, our purpose-built factory harnesses solar power, underlining our pledge to low-impact and sustainable manufacturing.

Sustainable Sourcing and Material Innovation

We actively partner with steel mills that produce recycled steel. Our commitment to sustainability extends to sourcing materials locally, further decreasing our carbon footprint in the supply chain. This dedication to environmental responsibility underscores our mission to create products that are not only strongly built, but also environmentally conscious.

Solar Power Integration

By utilizing solar power, we generate clean, renewable electricity to power our operations while significantly reducing our carbon footprint. This initiative underscores our commitment to sustainability, marking a significant step towards a greener future. Our new warehouse and office space, as of March 2023, houses a solar energy system capable of generating 400 kW of power per day, approximately 95% of our current energy consumption.

Transport Efficiency

Our in-house logistics team was integrated into our operations in 2022, to enhance transport efficiency and control over our delivery processes, ultimately delivering a far superior delivery experience for our customers. This strategic move allowed us to significantly reduce our reliance on national transport companies, which inherently contribute to a much larger carbon footprint for our products through the use of their multiple logistics centres, where they consolidate freight for delivery. By consolidating freight at our factory and delivering directly to your door, we significantly reduce the carbon footprint of each shed, and deliver a far superior delivery service in the process.

Greenfield Development

Easyshed's commitment to sustainability extends to taking extra measures to protect the local environment around our factory. Despite needing only 17,000sqm for construction, Easyshed acquired 57,000sqm of land to preserve local flora and fauna, planning to increase natural vegetation on the balance of land and give back to earth what we have taken. The factory is designed to maintain pre-development water flow levels, avoiding negative runoff effects. Strategically located in Albury, the site selection minimises our transport carbon footprint and supports regional employment, reflecting Easysheds' dedication to environmental responsibility and community support.

Our Progress in Numbers

70%

Work-from-home staff. This not only improves work-life balance, but also significantly reduces commuting-related emissions, and the need for large offices which further impact our environment.

500+

New trees and plants on site, and counting. Creating an ecosystem within our factory precinct that gives back to Mother Earth what we have taken.

95%

Reduction of paper usage within our organisation, with the only paper used being your checklist and assembly manual. This helps with our goal of reducing the devastating impact of forestry.

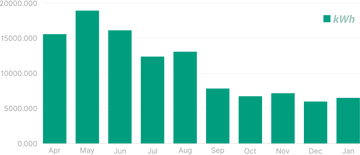

Power Progress

We’ve minimised emissions related to our electricity consumption with the investment into solar power.

What’s in our future?

Plastic Elimination

Striving for a plastic-free future and a paperless organisation, we are actively working to eradicate all plastic usage within our operations by the year 2026.

100% Renewable Electricity

Whilst we are generating more electricity than we use through solar currently, the next stage is the installation of a commercial battery, so we are 100% renewable even when its dark! Timeframe = 2025.

Hydrogen-Powered Vehicles

We envision a future where all our delivery trucks are powered by hydrogen. Trials begin in 2025, with a full fleet transition by 2028.